Carbonaide is strengthening its commercial delivery capabilities as two new technology installations are underway in Finland and international sales continue to grow. To support this momentum, Petri Mäkelä has joined the team as Customer Solution Engineer, bringing extensive experience in project delivery, manufacturing, and logistics from industries such as mining and heavy manufacturing.

With industrial-scale proof of the benefits of carbon dioxide curing of concrete and a standard fitting solution that integrates seamlessly into existing production lines, Carbonaide is providing the concrete sector with the tools it needs to scale low carbon concrete production globally.

“I’m looking forward to helping build Carbonaide into a world class partner for the concrete industry, with robust delivery and agile customer care,”

comments Petri about his new challenges.

Future-proof Concrete Technology Must Meet Its Expectations from Day One

Concrete producers are under pressure to deliver high-performance, low-emission products without disrupting their existing operations. Carbonaide’s commercially ready CO₂ curing system is designed for fast delivery and smooth integration. The installation process is completed within a tight time window and does not interfere with ongoing concrete production.

Petri Mäkelä’s background in project and quality management ensures that Carbonaide’s technology deliveries meet the high standards of the concrete industry. His expertise supports our commitment to providing a care-free, fast delivery experience for our customers.

Discover how we support our customers: Carbonaide Care

Carbon Dioxide Curing Has Shown Its Benefits on Industrial Scale

The first producer to adopt Carbonaide’s solution, Rakennusbetoni- ja Elementti Oy, has successfully launched products into the Finnish construction market. These products, manufactured using Carbonaide’s CO₂ mineralization process, have demonstrated both technical performance and growing demand among end-users.

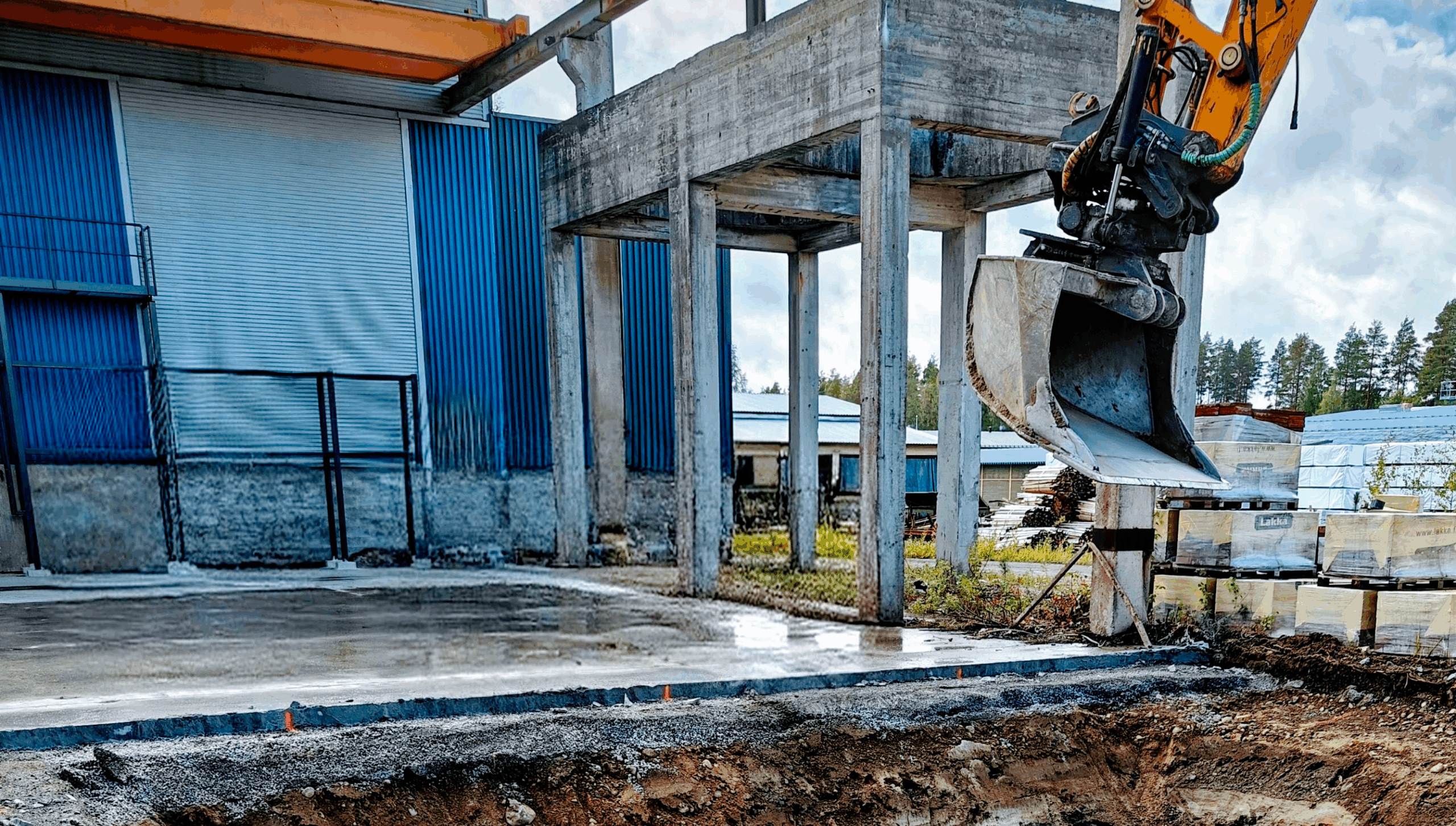

Following this success, Lakan Betoni Oy has invested in Carbonaide’s technology. Their installation will be operational in early 2026, increasing the availability of low carbon concrete products by five to ten times. This expansion reflects the rising interest in emission-reducing solutions and the proven quality of Carbonaide’s technology.

Read more about Lakan Betoni’s investment: Lakka adopts Carbonaide’s technology

A Care-Free Way to Enter Cheaper, Faster, Stronger and Greener Concrete Production

Carbonaide’s solution enables concrete manufacturers to utilize and store carbon dioxide in their products, reducing greenhouse gas emissions while improving mechanical properties and cement savings. Our technology offers a care-free path to increased production capacity and lower emissions—without disrupting your existing processes.

Explore our technology platform: Optimize the footprint of concrete

About Carbonaide

Carbonaide turns building materials from a large emission source into a carbon sink. With the Carbonaide Service Platform, you can utilize carbon dioxide in concrete production and permanently store carbon as carbonates in building materials. This process, known as CO₂ mineralization, enables sinking carbon dioxide into concrete products ensuring permanent carbon storage without sacrificing the quality of the concrete.