We are pleased to announce that Carbonaide has officially commenced project implementation at the Lakan Betoni customer site. This marks a significant milestone in deploying our carbon dioxide curing systems and our quest to transform concrete manufacturing into a carbon sink.

Foundations Laid for Low-Carbon Concrete Production

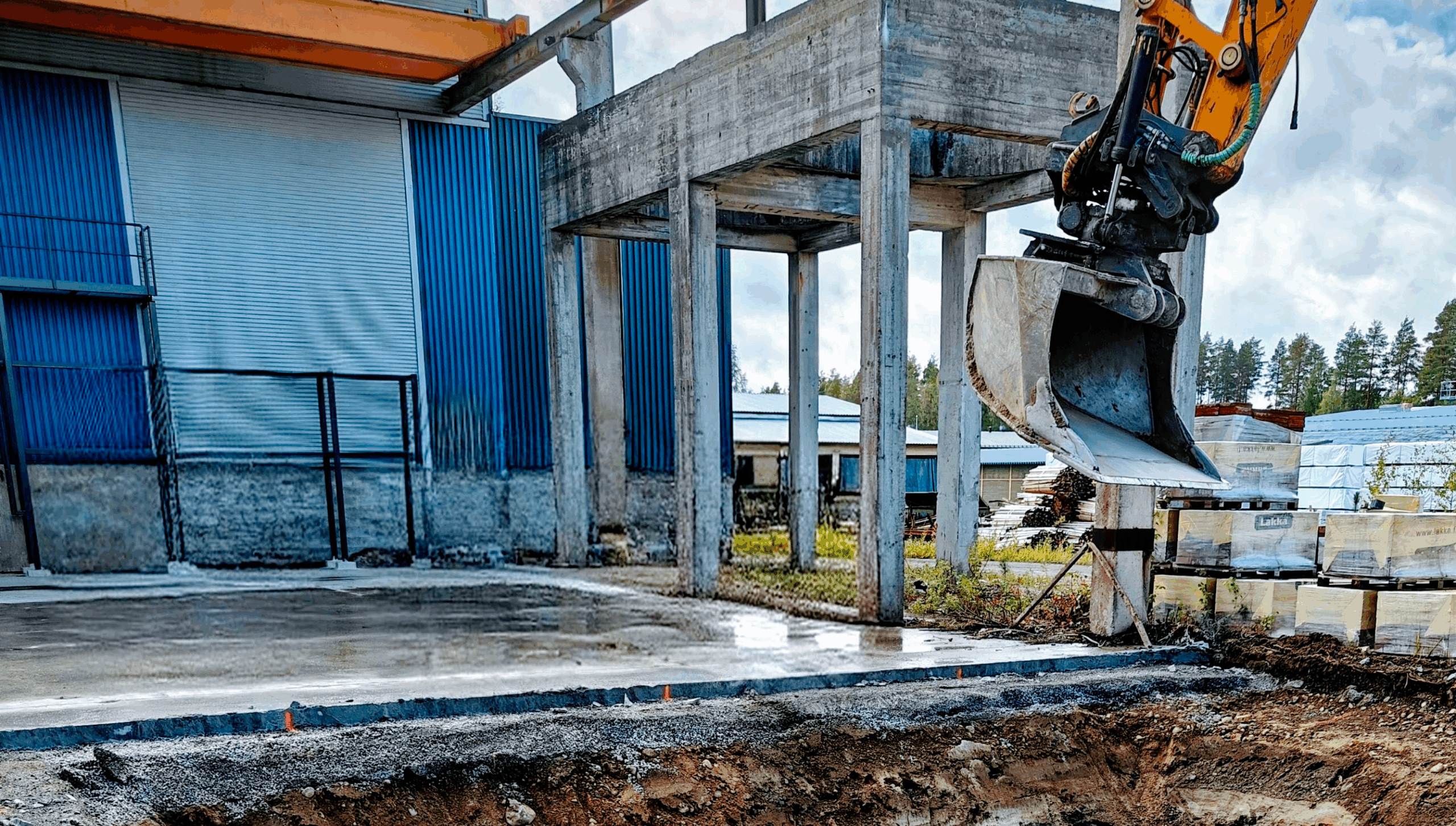

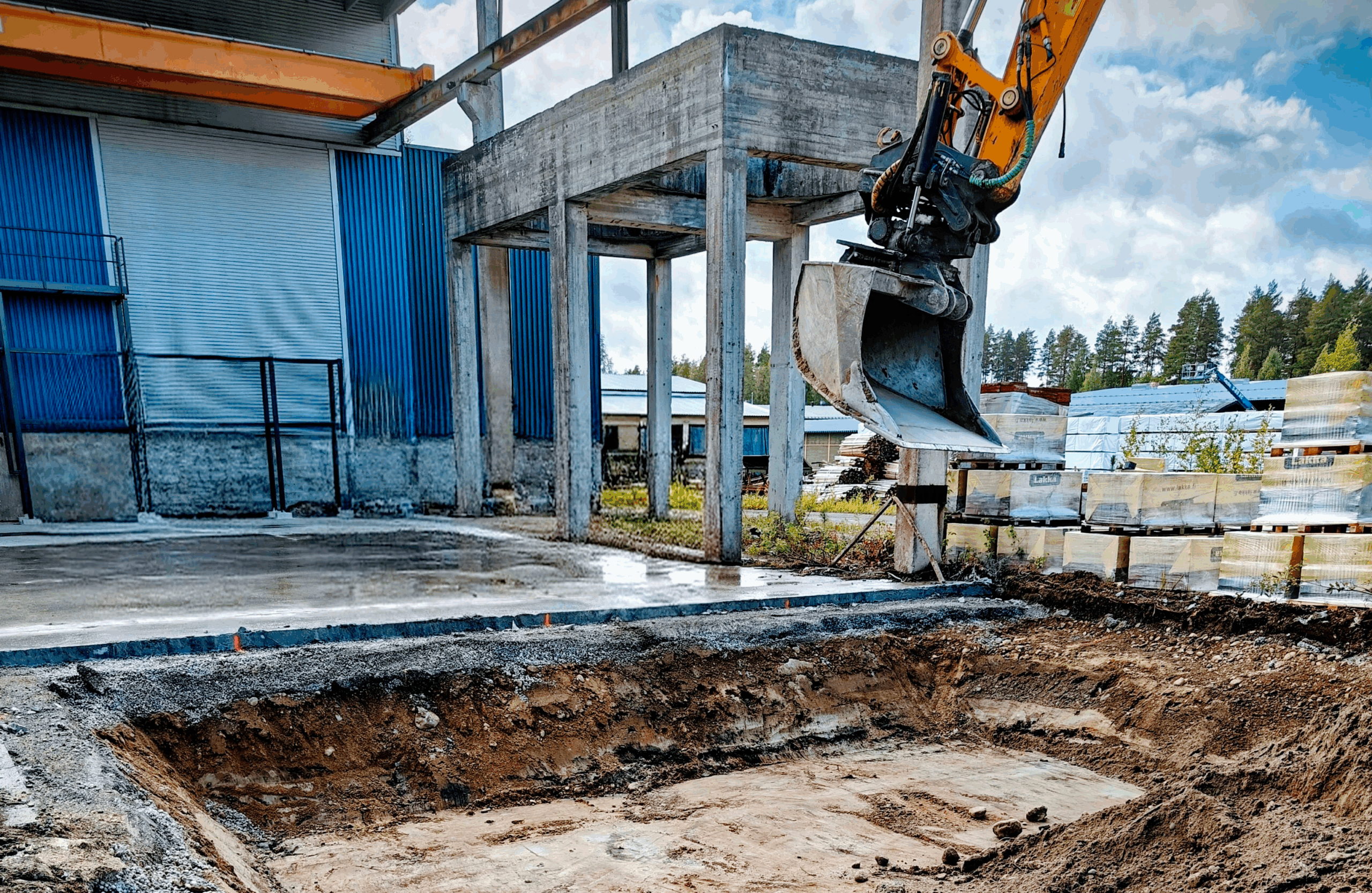

The initial phase is now underway, with construction of the foundations for the CO₂ tank and installation of support structures for ductwork and maintenance platforms. In parallel, Carbonaide process containers are being equipped with process devices and the CO₂ flow management system. These preparations set the stage for the full-scale on-site installations scheduled to begin in early November.

Installations Set to Accelerate in November

The upcoming installation phase will focus on constructing the process containers, CO₂ tank, and ductwork, as well as sealing the existing curing chambers to become gas-tight according to our specifications for the mineralization process that permanently stores carbon dioxide in concrete products.

After the installations, there will be a test and optimisation period. The production start is planned for the first quarter of 2026.

Business Value Through Carbon Dioxide Curing

Carbonaide’s proven technology not only suppors emission reductions but also unlocks operational benefits. The CO₂ curing system enhances mechanical properties, shortens curing times and enables cement savings. For Lakka as our customer, the carbon dioxide curing opens new possibilities for new low-carbon products.

By reducing cement content, manufacturers can lower both emissions and production costs. The mineralization process forms stable carbonates that strengthen the concrete, allowing for faster hardening and improved material performance.

Additionally, the technology supports the use of alternative Supplementary Cementitious Materials (SCMs), expanding the range of usable inputs and further optimising the carbon footprint of concrete production.

Permanent Storage with Economic Upside

Beyond production efficiency, Carbonaide’s CO₂ curing system offers verified permanent carbon storage. This stored carbon can be accounted for in emission reporting or monetised through carbon credit management in voluntary markets.

We at Carbonaide are proud to be solving hard problems in the built environment. This project implementation is a major step on our way to transforming the construction industry.

About Carbonaide

Carbonaide turns building materials from a large emission source into a carbon sink. With the Carbonaide Service Platform, you can utilize carbon dioxide in concrete production and permanently store carbon as carbonates in building materials. This process, known as CO₂ mineralization, enables sinking carbon dioxide into concrete products ensuring permanent carbon storage without sacrificing the quality of the concrete.