Lipa-Betoni is making history by becoming the first precast concrete manufacturer in the world to implement Carbonaide® technology at its factory in Finland. This innovation enables permanent storage of carbon dioxide in concrete elements, reduces cement use, and significantly lowers the carbon footprint. Pilot operations will begin in early 2026, with full-scale production to follow soon after

“We are proud to be pioneers in this globally significant transition,” says Satu Lipsanen, CEO of Lipa-Betoni. “This upgrade covers the entire capacity of our factory, allowing us to supply low-carbon concrete elements widely already during 2026.”

The construction industry, especially in Europe, is set to transform toward decarbonization. This transformation is driven by two factors: carbon taxation across Europe and market-based building regulations. Overall, companies that quantify material emissions, integrate CO₂ storage, and document recyclability will gain a competitive and regulatory advantage.

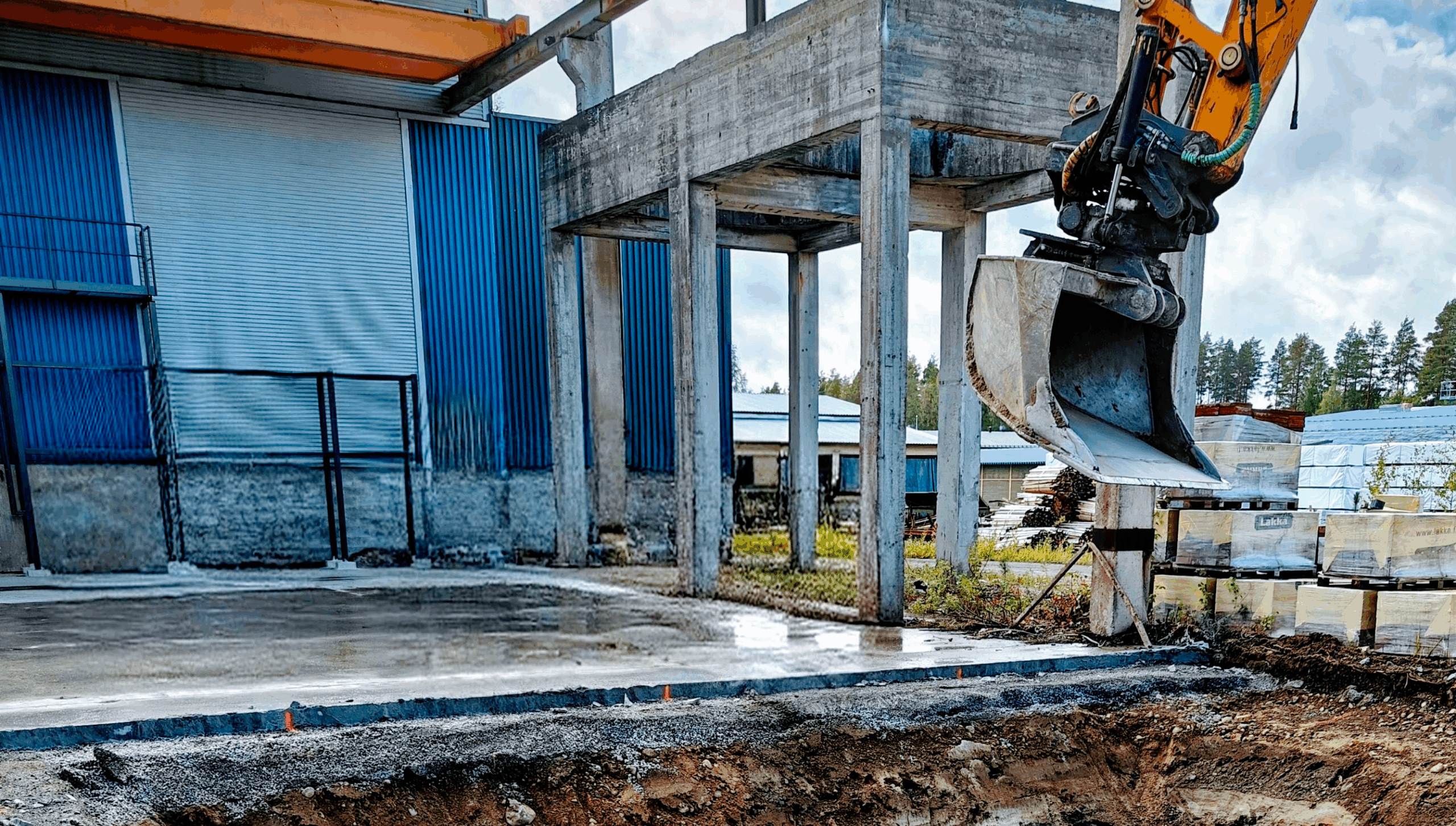

Construction in progress – implementation to begin in early 2026

The factory investment project is currently underway at the factory, where Carbonaide’s systems are being integrated into Lipa-Betoni’s full-scale element production. The work includes module manufacturing, tank installations, and system integration. After these phases, pilot operations will start at the beginning of 2026, followed by full production.

A partnership with Elematic enables customers to adopt the technology in existing factories in Europe

Our technology partner Elematic has developed a specialised sealing solution for the factory’s curing chambers, where a patent is pending, enabling the safe use of carbon dioxide in the production process.

According to Tapio Vehmas, CEO of Carbonaide, Lipa-Betoni’s project marks a crucial milestone in the company’s commercialization process: “We are now entering the precast concrete industry together with Lipa-Betoni. This first full factory integration also represents a major step in our collaboration with Elematic, started in 2025, which allows us to bring our solution rapidly to Europe’s construction markets.

Potential for decarbonisation and cost savings in the construction sector

Carbonaide’s technology allows for a reduction of up to 20% in cement usage. In addition to being cost-effective, this technology also accelerates the manufacturing process, minimizes climate impact, and addresses the increasing industrial demand for low-carbon construction solutions.

“Teppo Voutilainen, CEO of Elematic, adds: “Europe faces a significant step change towards decarbonization in construction. Carbonaide’s technology provides our customers with a more efficient, lower-emission way to manufacture precast concrete while reducing costs. Elematic can fully support the implementation of this technology into existing precast factories.”By combining Elematic’s expertise in equipment and automation with Carbonaide’s carbon dioxide treatment process, the collaboration enables the production of more sustainable concrete elements that permanently store CO₂.

Lipa-Betoni aims to achieve over 60% emissions reduction in its element production in the first phase of adopting Carbonaide technology, surpassing Finland’s current low-carbon classification standards for concrete.

About Carbonaide

Carbonaide’s mission is to turn building materials from a large emission source into a carbon sink. With the Carbonaide CO₂ curing solutions, concrete manufacturers can utilise carbon dioxide to improve their production and permanently store carbon as carbonates in the products at the same time.