Home » Technology » Cement savings

Cheaper

Cement savings

Reducing the need for cement with Carbonaide

Carbonation during concrete hardening, or CO₂ curing as we call it, reduces the amount of cement needed in concrete.

The Carbonaide CO₂ curing technology enables multiple ways to reduce cement content in concrete production, enabling lower emissions and production costs. Depending on the product-specific requirements, various methods can be used to optimize the concrete mix design and the curing process.

The cement content reduction has three main mechanisms:

Faster hardening

Faster hardening with CO₂ reduces the need for excess cement. The reduction can be substantial, especially in products with low packing strengths, which typically need excess cement for good early-age strength development to meet standard requirements.

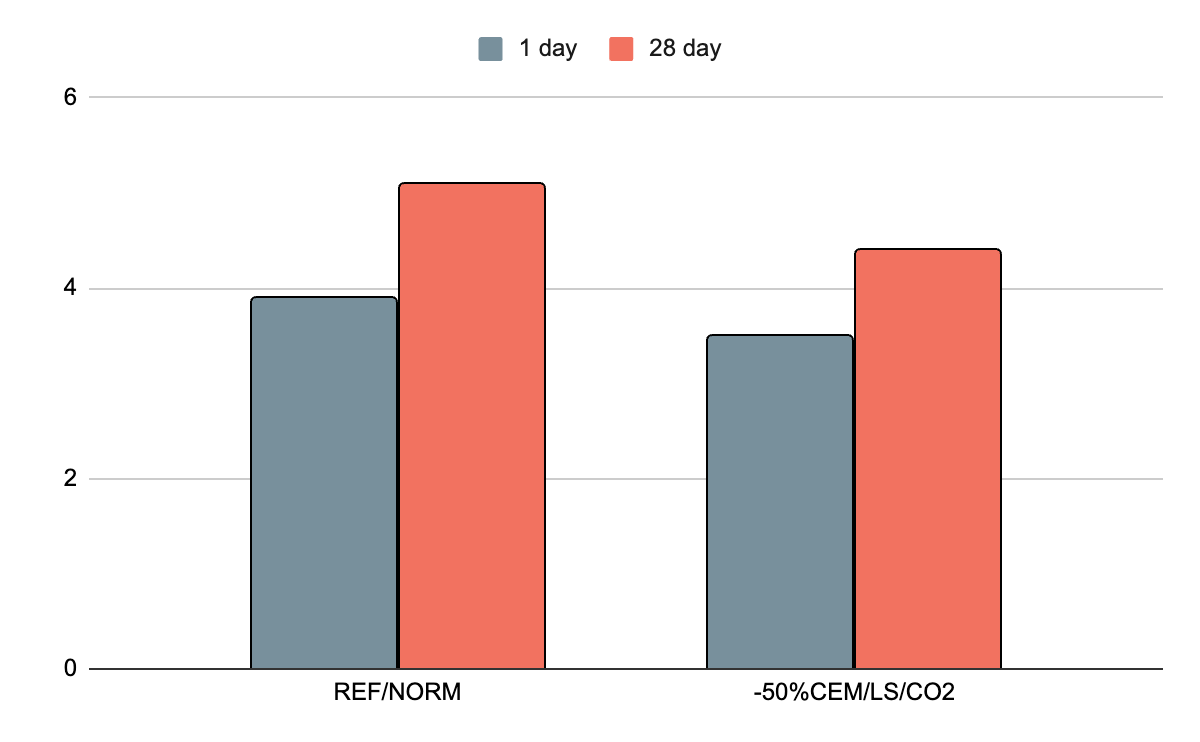

The figure beside shows the effect of CO₂ curing for light-weight structures in early strength development. In this case, CO₂ curing allowed 50% of the CEMI of the reference product to be replaced with limestone.

Increased density

Carbonation makes concrete more dense. CO₂ curing enables densification of microstructures of the concrete via different mechanisms, resulting in better mechanical properties. This in turn permits reducing the cement content compared to traditionally manufactured products.

New SCM alternatives

Carbonation enables a large variety of new type Supplementary Cementitious Materials (SCMs). This happens in two ways: Carbon curing can either activate the reactivity of otherwise passive materials, or the CO₂ introduced to the concrete during curing forms new reaction products with the SCM. A well-known example of passive material activation is the carbonation of gamma dicalciumsilicate. Gamma dicalciumsilicate is present in freely cooled mixtures of calcium and silicate. Various iron and steel processes form gammadicalciumsilicates. In normal concrete production, these slags are non-reactive and cannot be used, but in the presence of CO₂, gamma-C2S is an excellent binder.

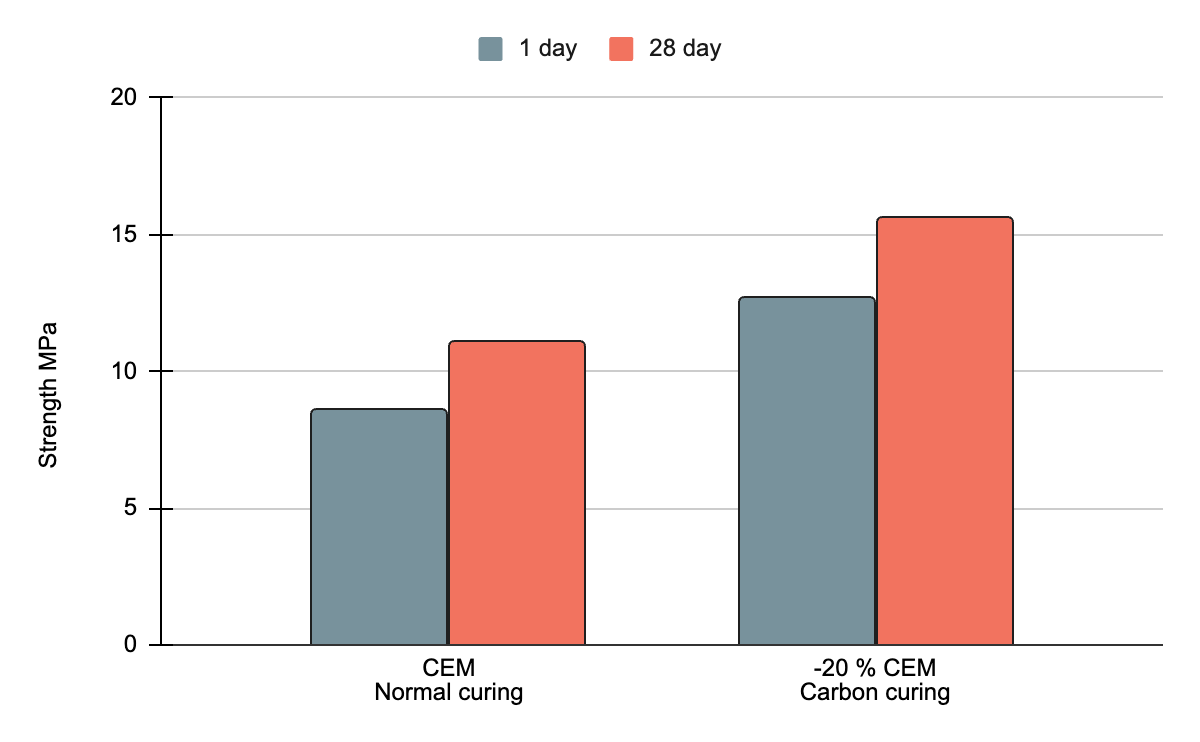

In the figure beside, you can see an example of concrete production where the Carbonaide CO₂ curing process allowed 20% of the cement to be replaced with a calcium-rich material.